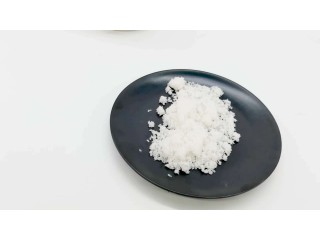

Poly(Dimethylsiloxane) cas 9016-00-6 Manufacturer & Supplier

Sep 26th, 2022 at 15:33 Electronic Chemicals Rossmoor 54 views Reference: Oy5eV565dEPLocation: Rossmoor

Price: Contact us

Poly(dimethylsiloxane) Cas 9016-00-6 - Buy Poly(dimethylsiloxane),Cas 9016-00-6 Product manufacturer and supplier from China, Please contact us by Live Chat on the bottom right.

Essential details

| Classification: |

Chemical Auxiliary Agent |

| CAS No.: |

9016-00-6 |

| Other Names: |

SILICONE FLUID |

| MF: |

C5H6Si |

| EINECS No.: |

618-493-1 |

| Purity: |

99% |

| Place of Origin: |

Shandong, China |

| Type: |

Chemical Auxiliary Agents |

| Usage: |

Surfactants, Textile Auxiliary Agents |

| Model Number: |

ZXY |

Supply Ability

| Supply Ability | 1000 Metric Ton/Metric Tons per Month |

Packaging & delivery

200kg/DrumQingdao;Shanghai

| Packaging Details | |||||||

| Port | |||||||

| Picture Example: | |||||||

| Lead time: |

|

Product Description

Poly(dimethylsiloxane) Quick Details

Chemical Name:Poly(dimethylsiloxane)

CAS NO.: 9016-00-6

Molecular Formula: C5H6Si

Molecular Weight: 94.18664

Appearance: A colorless viscous liquid

Poly(dimethylsiloxane) Typical Properties

| Test Items | Specification | Test Results |

| Color And Appearance | Colorless liquid | Conform |

| Odor | Non | Conform |

| Density | 0.850 ~ 1.050 | 0.950 |

| Viscosity | 10-1000m/Pa | 200m/Pa |

| Densities | ≤ 0.05% | 0.0011% |

| Refractive Index | 1.4005-1.4045 | 1.4041 |

| LOD | Not more than 2.0% | 0.8% |

| Heavy Metals | No more than 0.0005% | Passed |

| Arsenic Salt | No more than 0.0002% | Passed |

| Conclusion | Testing Results As Standard of In house |

Poly(dimethylsiloxane) Usage

1. Silicones are polymeric materials having silicon and oxygen on their composition. They are largely inert compounds usually heat-resistant, nonstick, and rubberlike.

2. Polydimethylsiloxane (PDMS, molecular formula (C2H6OSi)n, density 965 kg/m3, boiling point: < 200℃, shear modulus between 100 kPa and 3 MPa, loss tangent less than 0.001) is a viscoelastic polymer (elastomer).

3. PDMS is widely used in microfluidic technology thanks to some of its unique properties: it is low cost, nontoxic, chemically resistant, and stable against humidity and temperature variations.

4. PDMS also presents low interfacial energy, which allows it to avoid chemical interactions with other polymers and solutions in the microfluidic channels. After polymerization and cross-linking, solid PDMS presents hydrophobic surface. A treatment using plasma oxidation is frequently used to alter the surface chemistry by adding silanol (SiOH) groups to the surface terminations and make the surface hydrophilic (wettable).

5. PDMS is usually used as sealant, structural microchannel material or elastomer stamping matrix in soft lithography techniques like microcontact printing and micromolding.

6. Poly(dimethylsiloxane) is an antifoaming agent used in fats and oils. It prevents foaming and spattering when oils are heated and prevents foam formation during the manufacture of wine, refined sugar, gelatin, and chewing gum. It is also termed methyl polysilicone and methyl silicone.

Poly(dimethylsiloxane) Packaging and Shipping

200kg/drum.

Company Information